Ergonomics and wellness at work

The importance of ergonomics for the well-being and safety of workers

The science that studies the interaction between human beings and the elements they use is called ergonomics (from ergon: work and nomia: management). Ergonomics is therefore the science that optimises tools, technologies, systems and applies them to design to improve the well-being of those who use them.

What are the main concepts of ergonomics?

The primary purpose of ergonomics is to improve the performance of workers, their well-being, and to protect their health and safety.To achieve this, ergonomics evaluates the positions assumed by the body during repetitive actions to eliminate, or at least reduce, psychophysical stress and the risk of injury.

How is ergonomics evaluated?

To evaluate the quality of ergonomics, ergonomists must take into account the characteristics of the human being and his demands, the environment in which he moves, the type of work he does and the tools he uses.

The scientific disciplines on which ergonomics is based are many and varied: the aim is to make tools compatible with human abilities.

To make an ergonomic product, therefore, it is necessary to study human factors, anthropometry, biomechanics, physiology, psychology, kinesiology, physics, engineering and, of course, industrial design.

What does the legislation provide for ergonomics?

Article 15 of the Consolidated Occupational Health and Safety Act (Legislative Decree 81/08) stipulates that in the organisation of work, workers are not exposed to the risk of accidents, injuries or occupational diseases.

Legislative Decree 626/94 and Presidential Decree 459/96 refer to various ergonomic principles to regulate the improvement of safety and essential requirements.

However, it is the various UNI ISO and UNI EN standards that define the general principles of ergonomics and regulate various aspects in detail.The UNI ISO 11226-11228 standards establish, for example, the limits of Biomechanical Overload in Manual Handling of Loadswith regard to lifting, transport, pushing, pulling, frequency as well as assessing static working postures.The UNI EN ISO standards on Anthropometry, on the other hand, define the techniques for measuring the human body during the design phase, the three-dimensional scanning methodologies and the requirements for templates or dummies for testing functions.

The UNI EN standards on Machinery Safety establish principles for the design of ergonomic and safe devices, in terms of usability and performance.

The UNI EN ISO 9241 standard on Man-System Interaction defines guidelines on the accessibility of information technology equipment and services.

How do you improve the ergonomics of a product?

If a tool is difficult to use, uncomfortable or unsafe, it is considered unergonomic.

A product is ergonomic when it safeguards the health and well-being of the user and enhances user satisfaction.

Ergonomic suitability is achieved by relying on the kinetosphere, the science that measures man's prehensility and ability to move in the space around him, ideally represented as spherical.

In the production environment, one may decide to implement a reactive ergonomics plan, if a product needs to be corrected, or preventive ergonomics if one wants to identify problems in advance and then proceed to design.

Ergonomists and/or specialised companies can improve ergonomic suitability by assessing products and posture during use, as well as officially certifying the level of ergonomics.

Which products can be certified on ergonomics?

The International Ergonomics Association, with more than 42 member associations, is the association that promotes the application of ergonomics to more sectors in order to improve the quality of life.

A large number of consumer products (e.g. mattresses, pillows, irons, etc.), professional equipment and products (e.g. chairs, industrial laundry equipment, seat openers), work environments (e.g. video terminals), processes (e.g. human centred design, digital systems approach) can be certified on safety and comfort.

How do you certify an ergonomic product?

To certify a product or process, it is necessary to apply to the relevant ergonomics certification bodies.

The ergonomics certification process involves an initial analysis, followed by tests and verifications in the context of use.

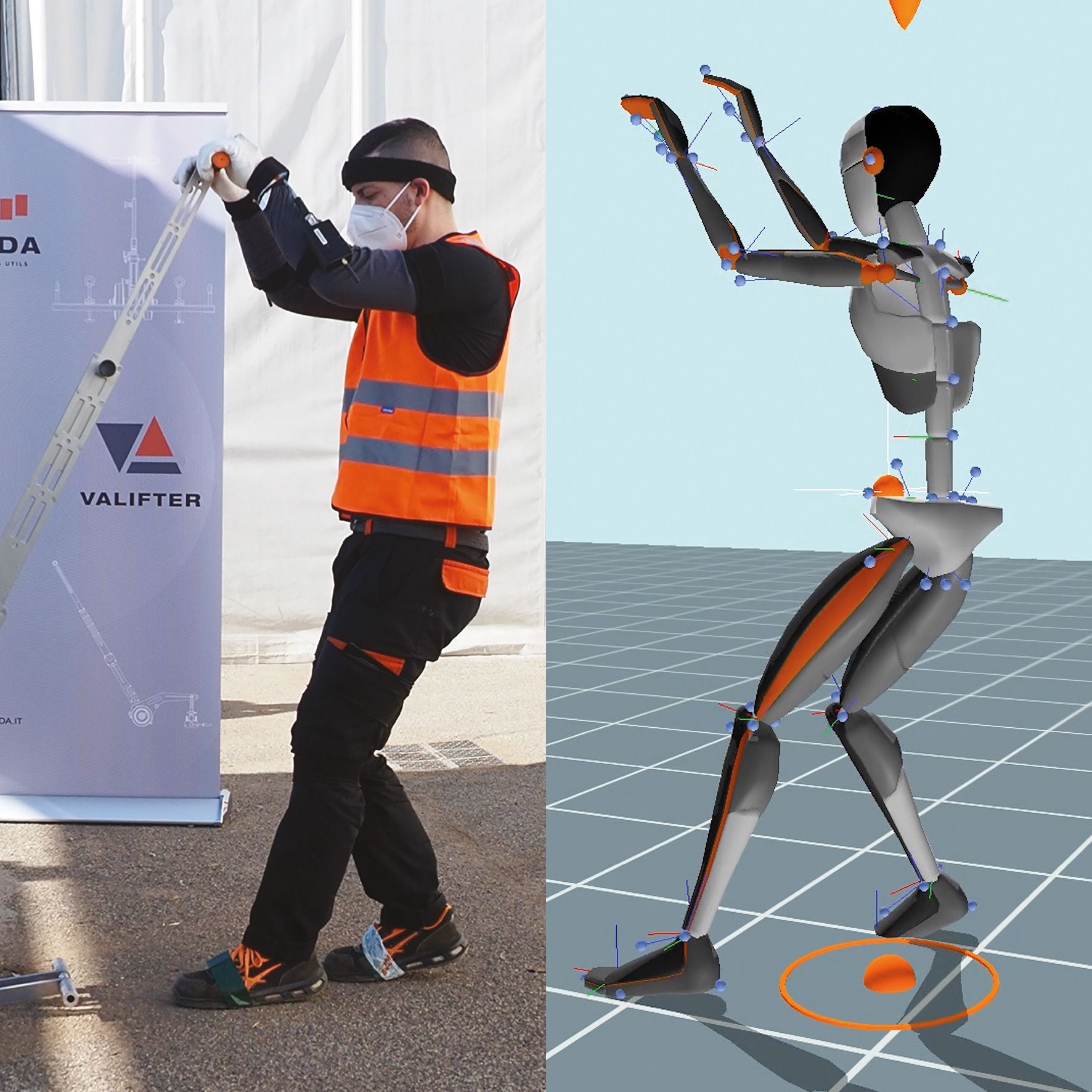

After carrying out biomedical, usability and user experience tests, also with the aid of 3D simulation tools, and requesting any adjustments, the certification body develops a report and can proceed to issue the certificate.

FEDA turned to Ergocert the first internationally accredited certification body, to certify the ergonomic characteristics of the new Manhole Cover Lifter Liftop by brand ValifterErgocert evaluated Liftop using state-of-the-art instrumentation including pressure sensors, sensorised gloves, wi-fi motion capture systems, eye tracking to detect operator movement, posture, estimate load level and muscle activation GUARDA IL VIDEO